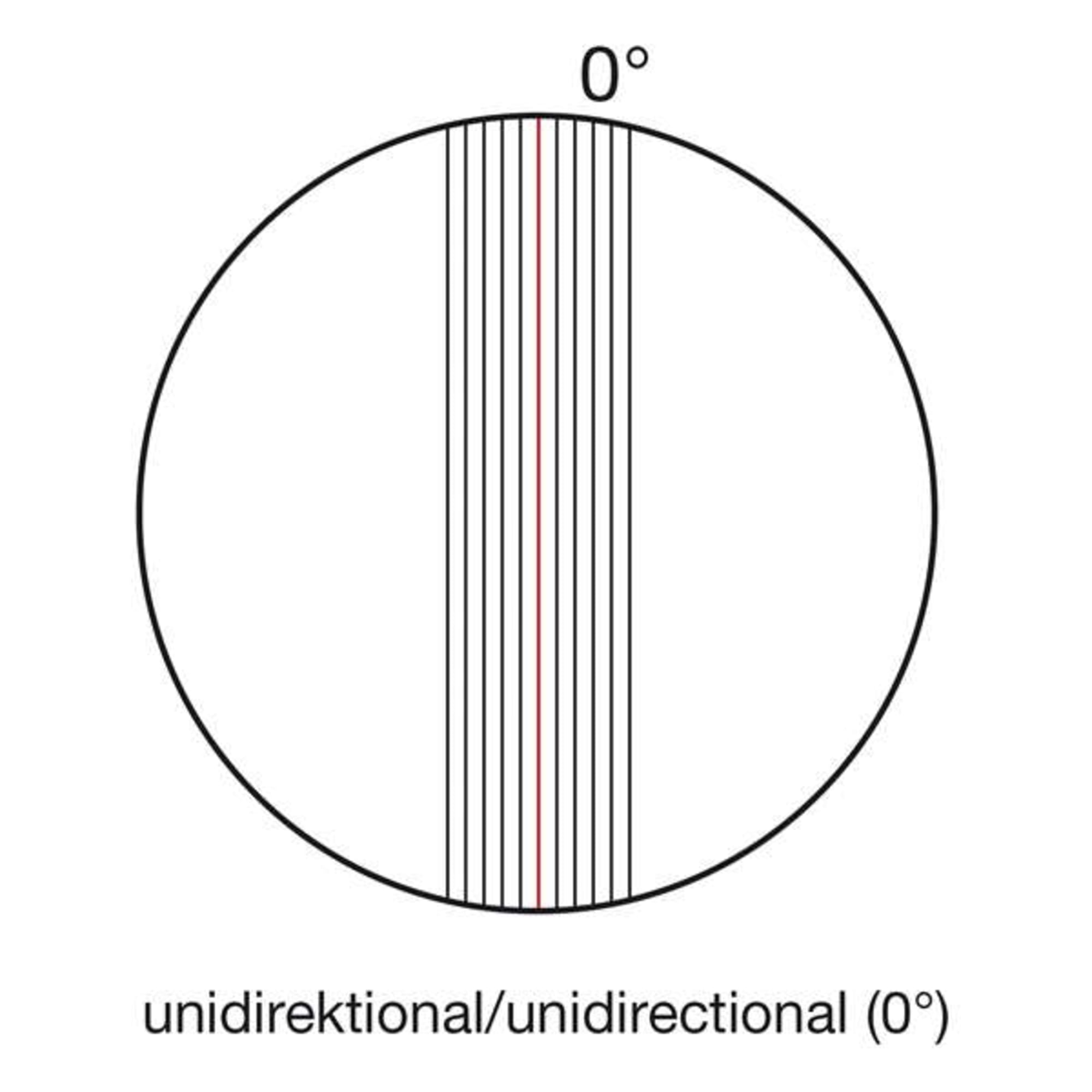

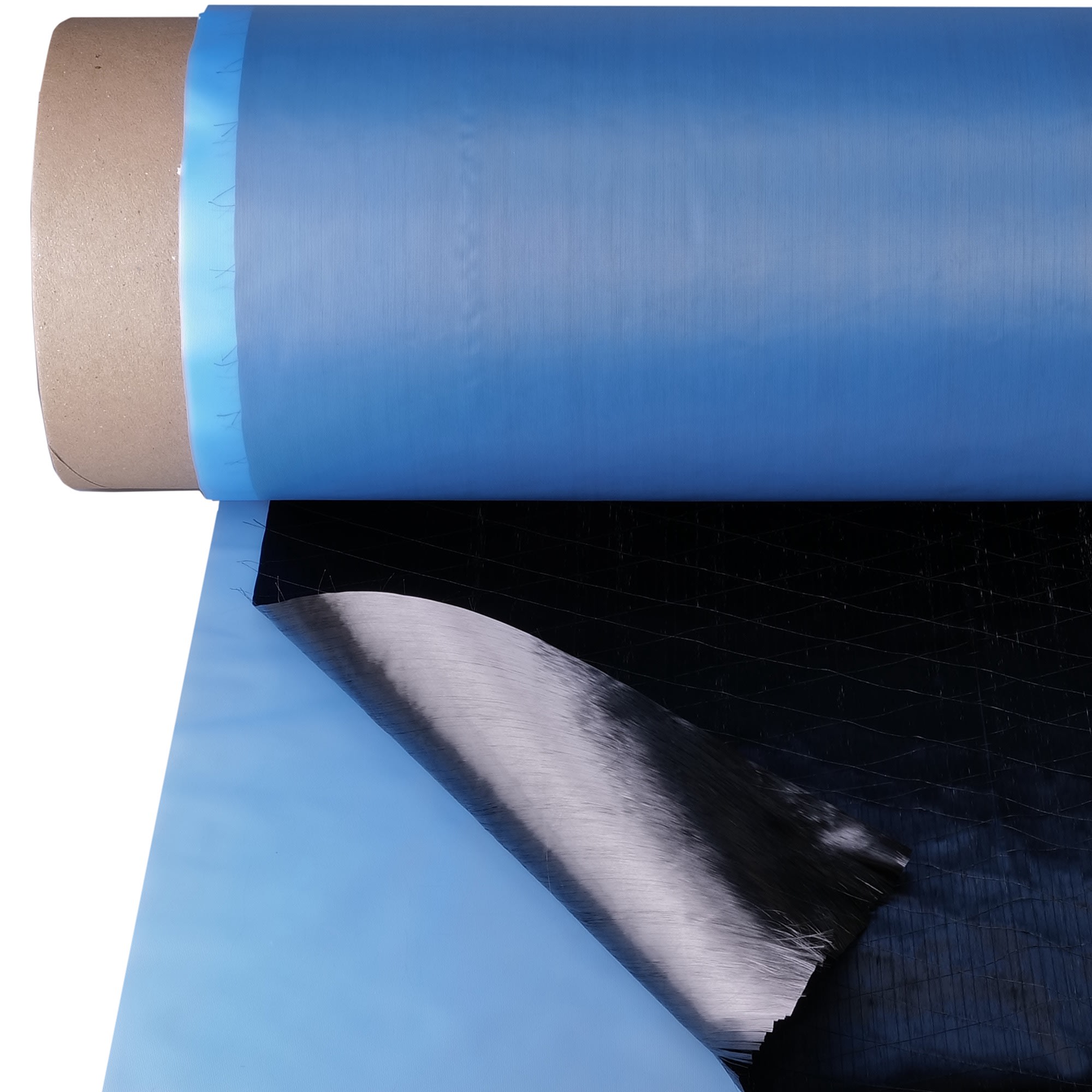

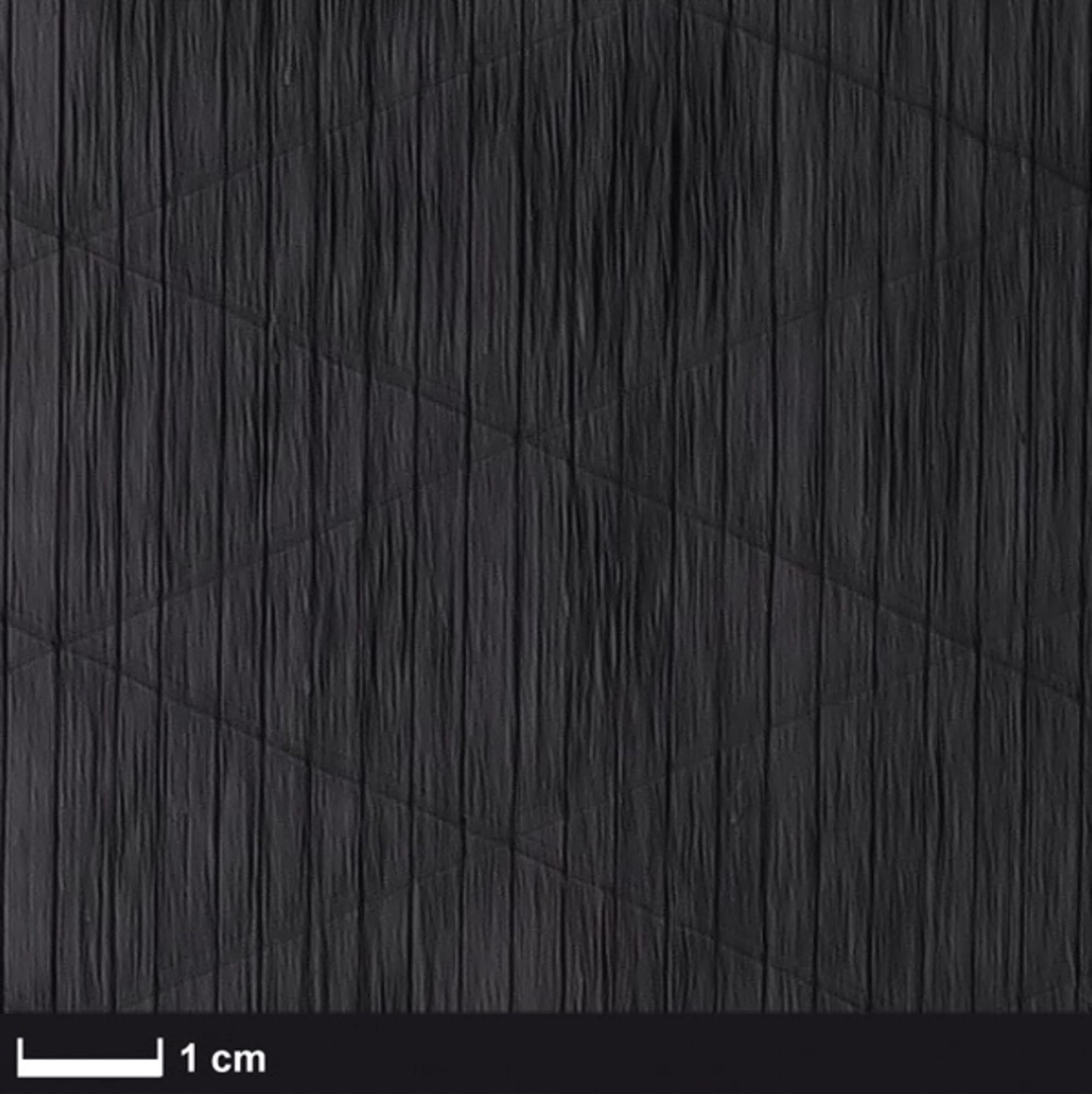

Carbon non-crimp fabric ST 400 g/m² (UD) 50 cm

USA: width 19.69", weight 11.8 oz/yd²

Fibre: ZOLTEK™ PX35 50k

Yarn titer: 50k, therefore low-priced, without loss of quality

Width: 50 cm

Technical data:

Tensile strength: 4137 MPa

Tensile modulus: 242 GPa

Elongation at break: 1.5%

Density: 1.81 g/cm³

Filament Diameter: 7.2 μm

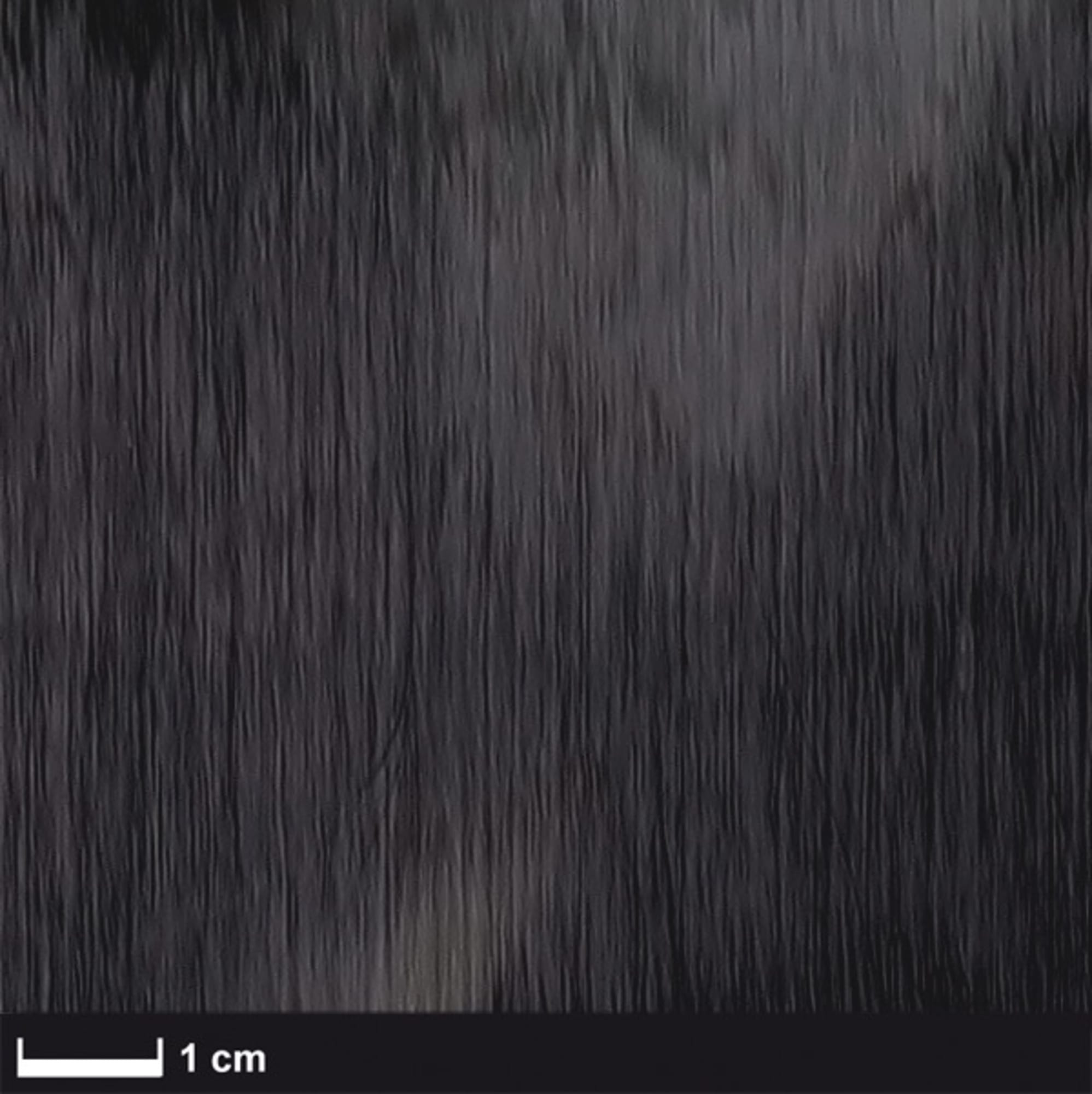

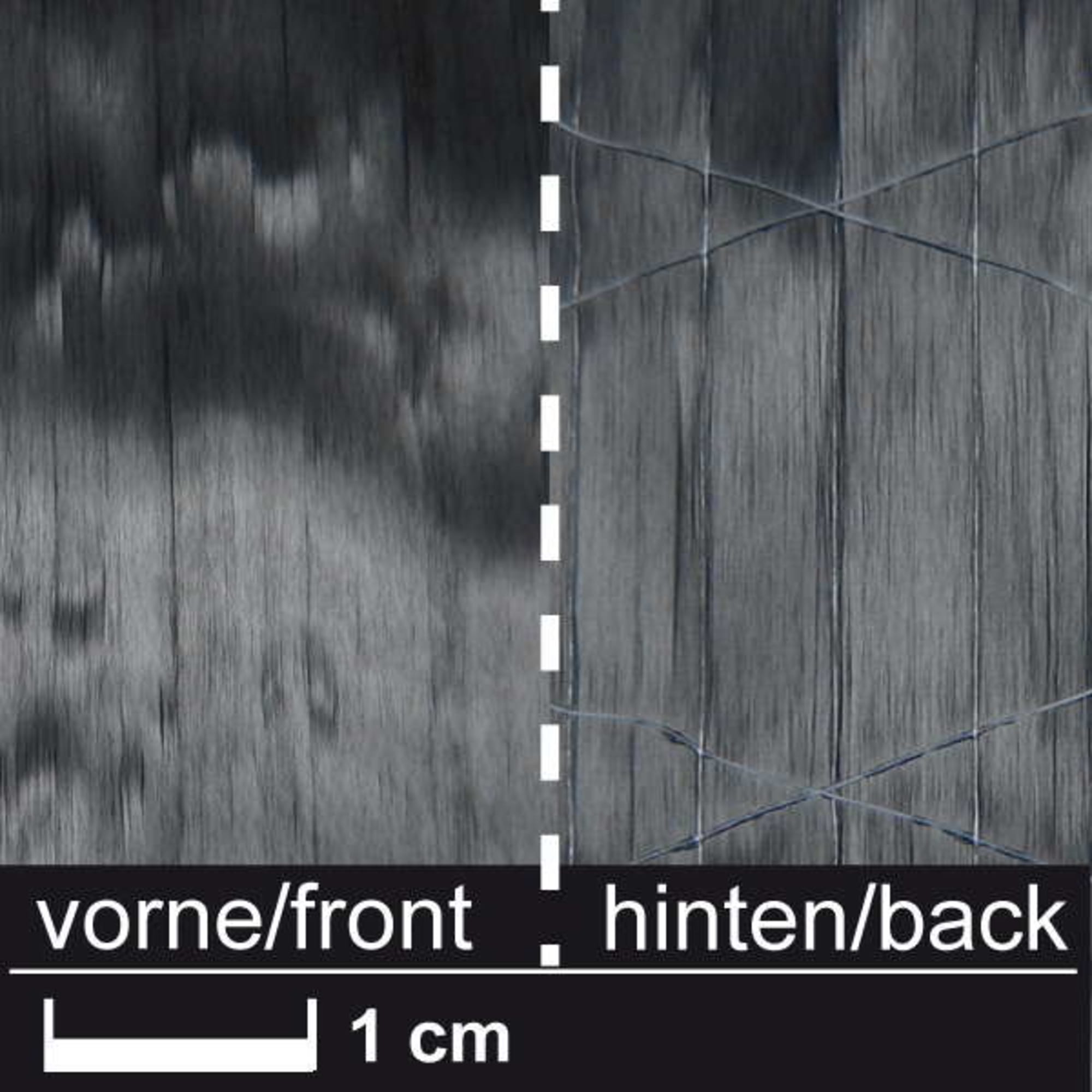

- All filaments are tensioned and absolutely parallel, not twisted to the right or to the left, so the fabric can fully utilize the properties of every single fiber, thereby the composite has excellent physical-mechanical properties.

- Thickness over the whole fabric’s width is consistent.

- All the physical parameters have very strict tolerance so the weight, fiber content, thickness, and width are very precise.

- Filaments are constrained by a very thin (76 dtex) polyester scrim (3.5 g/m², on both sides).

- The surface of filaments is smooth, therefore it is very handy to process.

Application:

Coatings and laminates in model construction, sandwich components, and technical components, are mainly loaded in bending. Advantages of the material: Lying absolutely flat, almost 100 % utilization of fibre properties, above all considerably higher compressive strength than fabric, higher fibre content possible, all cuts possible without fraying.

Calculated data for hand laminates with 45 volume percent fibres:

Resin consumption: 317 g/m², laminate thickness: 0.50 mm, laminate weight: 717 g/m²