Silicone moulding compounds

More Information:

| Silicone type | Description | Mixing ratio | Processing time | Demouldable | Heat resistance | Hardness Shore A | Colourable with R&G Universal colour pastes |

|---|---|---|---|---|---|---|---|

| KDSV-10 | Casting compound, white condensation-curing |

100 : 2 to 100 : 3 | 30 - 50 minutes (at 25 °C) |

4 - 5 hours (at 25 °C) |

short-time up to max. 200 °C |

10±2 | yes |

| KDSV-25 | Casting compound, white condensation-curing |

100 : 2 to 100 : 3 | 30 - 40 minutes (at 23 °C) |

3 - 5 hours (at 25 °C) |

short-time up to max. 200 °C |

25±2 | yes |

| KDSV M 4470 |

Casting compound, red-brown Suitable for casting |

100 : 2 to 100 : 3 |

20 - 40 minutes |

2 - 4 hours depending on curing agent quantity |

Continuous temperature resistance 200 °C short-time up to max. 300 °C |

60 | yes |

| ADDV-10-EC CRYSTAL CLEAR (not for mold making*) |

Casting compound, crystal clear addition-curing |

100 : 100 (= 1 : 1) |

30 - 60 minutes |

4 - 6 hours (at 25 °C) |

short-time up to max. 200 °C |

10±2 | no |

| ADDV-25 BLAU | Casting compound, blue addition-curing |

100 : 100 (= 1 : 1) | 30 - 50 minutes (at 25 °C) |

4 - 5 hours (at 25 °C) |

short-time up to max. 250 °C |

25±2 | no |

| ADDV-42 RED |

Casting compound, red Suitable for casting |

100 : 100 (= 1 : 1) | 30 - 50 minutes (at 25 °C) |

4 - 5 hours (at 25 °C) |

short-time up to max. 250 °C |

40±2 | no |

| ADDV M 4641 |

Casting compound, translucent FDA and BfR compliant, suitable for food |

100 : 10 (= 10 : 1) | 90 minutes (at 23 °C) |

15 hours (at 23 °C) (30 min. at 70 °C) |

Continuous temperature resistance 180 °C |

43 | no |

*) Not intended for mold making. Due to its low tensile strength, the ADDV-10 GLASKLAR system is only suitable for electro casting and similar applications.

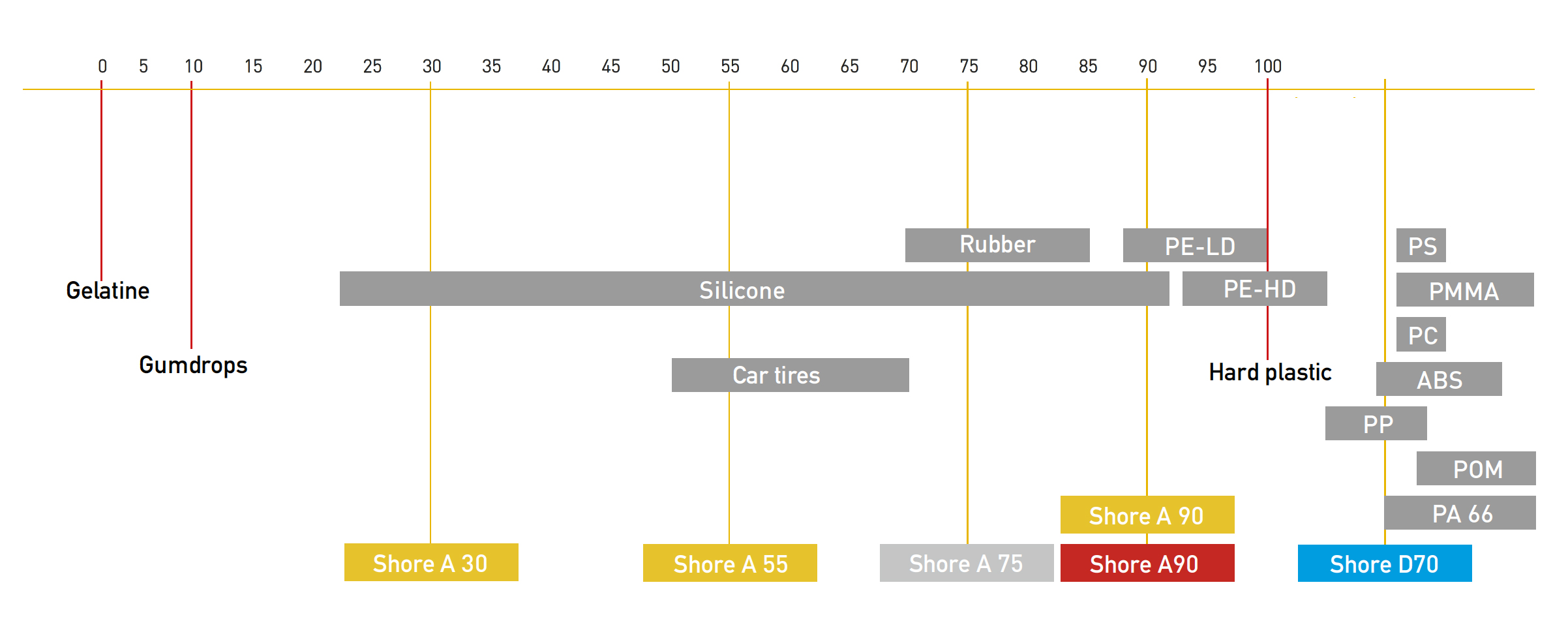

Shore A Hardness

Shore 0-20

Very soft silicones with very high flexibility. Suitable for moulds with pronounced undercuts.

Shore 20-40

Medium-hard silicones. The most common materials for impressions with undercuts and good dimensional stability.

Shore 40-80

Hard silicones. For self-supporting moulds, vacuum casting resins, and rapid prototyping.

Shore A Hardness scale - comparison table

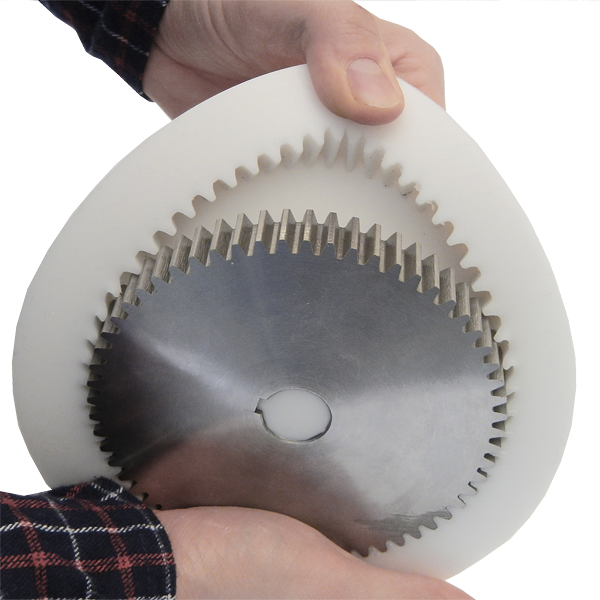

Highly flexible moulds made of silicone rubber allow the reproduction of complicated moulded parts with undercuts. The main areas of application are, for example, the production of model parts, furniture ornaments, relief images, decorative candles, architectural models, decorative buttons, doll bodies, sealing profiles as well as reproductions in monument conservation.

Master models made of the usual materials such as wood, metal, plastic, plaster, stone, and wax are well suited for impressions with silicone rubber. All silicones are self-releasing, no release agent is required. More information on the product.

We distinguish two curing systems:

RTV-2 silicones condensation curing (e.g. R&G silicones KDSV-10, KDSV-25 and KDSV M 4470)

Mould making

In condensation curing, the B component is added to the A component in a proportion of between 2 % and 5 %. During curing, a volatile alcohol compound is formed as a decomposition product, which leads to slight volume shrinkage.

Acceleration of the curing by increasing the temperature is not recommended. The vulcanizate may only be thermally loaded after complete volatilization of the cleavage product.

Advantages

- No vulcanization disturbance due to inhibition.

- The vulcanization speed can be adjusted within certain limits by varying the curing agent quantities or selecting a slow or fast curing agent.

- Excellent reproduction accuracy and excellent release properties.

Colouration is possible with R&G universal color pastes.

Can be used for short periods up to max. 200 °C, KDSV M 4470 even up to 300 °C

RTV-2 silicones addition curing (e.g. R&G Silicones ADDV-10-EC CRYSTALCLEAR, ADDV-25, ADDV-42 and ADDV M 4641)

Mould making

The most important feature of addition crosslinking is a platinum-containing catalyst complex. This controls - depending on the product in the A or B component - vulcanization without the release of a fission product and thus without shrinkage. The crosslinking rate can be extremely accelerated after processing by adding heat.

- Acceleration of the reaction by increasing the temperature

- Irreversible crosslinking

- No weight loss during curing

- Very low shrinkage rate (< 0.1 %)

- No release of fission products

- Excellent reproduction accuracy and excellent release properties

Detailed selection aids for all silicones can be found in the R&G eWiki

Brochure with processing instructions here

The following YouTube films show how the processing works: