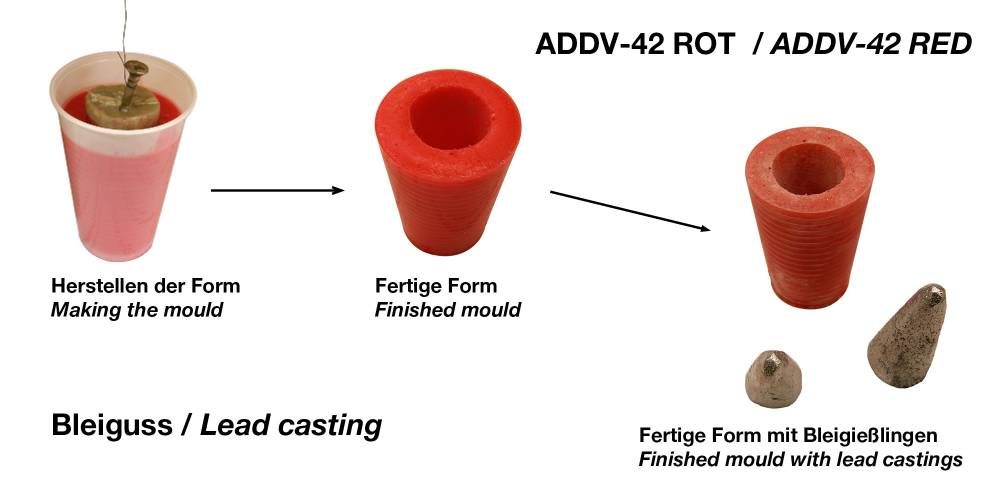

Silicone rubber ADDV-42 RED (set of two components)

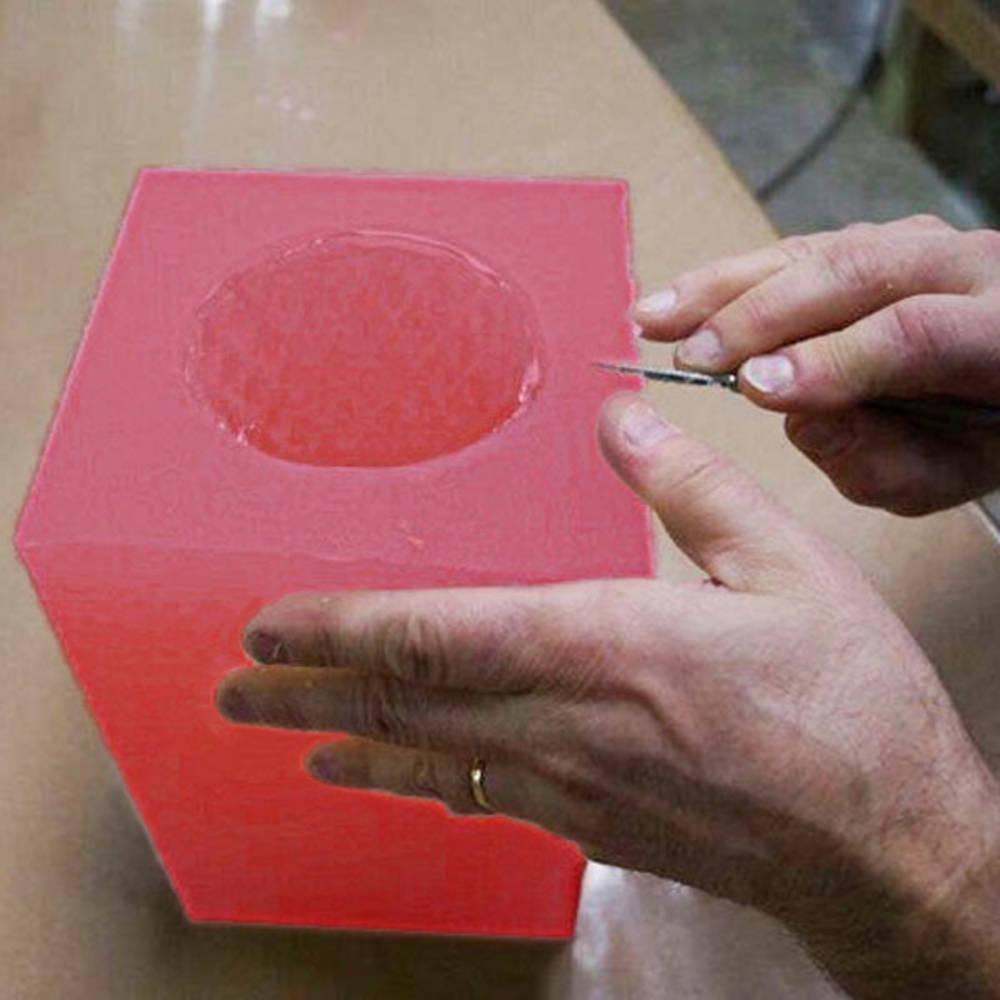

ADDV-42 RED is a castable, soft, addition-curing silicone rubber that has been specially developed for mould making. Its main features are its high elasticity and flexibility, which makes it ideal for moulding components with large undercuts. This means that the rubber can easily capture complex geometries and mould details without cracking or deforming. Thanks to its pourability, the silicone rubber can also flow into the smallest gaps, which enables high precision in mould production.

ADDV-42 RED cures without shrinkage, which could impair the accuracy of detail.

Properties:

- Good flowability

- Fast vulcanisation at room temperature

- Good tear and tear propagation resistance

Plaster and casting resins such as polyester resin, polyurethane resin and epoxy resin are particularly suitable for the production of replicas. To protect the moulds, we recommend the use of a wax release agent as a protective film, especially when casting with epoxy resin (see below).

Application:

- Particularly suitable for the reproduction of models with undercuts using polyurethane and epoxy resins

- Moulds with high thermal stability and heat dissipation for casting low-melting metal alloys (such as lead and tin, melting point: max. 250 °C). To increase the service life of silicone moulds for lead and tin casting, talcum powder can be used.

Processing:

Mixing ratio: 1 : 1 component A : component B

Processing time (at 25 °C): 30-50 minutes

Demouldable (at 25 °C): After 4-5 hours

No heat of reaction occurs during vulcanization so that even larger quantities (e.g. 10 kg) can be poured without the risk of overheating.

If heat is added during curing (e.g. in a heating cabinet or oven), the vulcanization time is reduced by half at a temperature increase of each 10 °C. The heat thus accelerates the cross-linking reaction. The maximum recommended curing temperature is 70 °C.

Please note:

- Cannot be processed with our Universal Colour Pastes.

- The air stirred in during mixing can be removed by vacuuming in a desiccator. This ensures that the silicone is free of air bubbles to the maximum.

- For all equipment and tools used, make sure that no other materials such as epoxy resins or condensation-curing silicones have been processed beforehand. Addition-curing silicones may react to impurities with curing problems.

Technical data:

Mixing viscosity: 5.800 ± 500 mPa·s

Shore A hardness: 40 ± 2

Tensile strength: ≥6.8 N/mm²

Elongation at break: ≥ 400 %

Tear resistance: > 12.5 N/mm

Linear shrinkage after 7 days at 23 °C: ≤ 0.1 %

Colour:

Component A: Translucent

Component B: Red

Additional information:

Delivery:

As both component batches are matches to each other, we only supply complete batches. It is not possible to obtain individual deliveries of silicone and catalyst.

Packs of 0.5, 1, and 2 kg are supplied in squeeze bottles and 10 and 20 kg in PE canisters.

Customer information:

The release agent Semiperm™ Monofilm in combination with PARTALL® Coverall Film PVA is suitable as a safe release agent for silicone moulds. This combination of release agents provides a barrier layer so that casting with epoxy resins is also possible without any problems. The service life (durability) of the molds is significantly extended.

The release agent Semiperm™ Monofilm is applied with a brush. After flash-off, PARTALL® Coverall Film PVA is applied, also with a brush or sponge. For more information on processing, see the release agents.

PARTALL® Coverall Film PVA is transferred to the casting, washed off with water after demolding and reapplied before each impression.