Fibre reinforcements - Peel ply

Peel plies from R&G – Reliable surface preparation for high-quality laminate products

R&G's peel plies are an indispensable material for anyone who wants to ensure a clean and adhesive surface for their laminate components. Our range includes various types of fabric that have been specially developed for different requirements.

These include plain weave fabrics, twill weave fabrics and narrow tapes for specific applications. Plain weave fabrics offer a uniform, dense structure that ensures a robust and consistent surface. Twill weave fabrics, on the other hand, are ideal for complex and curved shapes due to their greater flexibility. Our peel ply tapes enable precise applications and are perfect for protecting and preparing small or specific areas.

R&G peel plies meet the highest quality standards and ensures that your laminate remains clean and grease-free without additional sanding. It is universally suitable for epoxy, vinyl ester, and polyester resins. With our fabric types, you can achieve optimal results—from the manufacture of large components to precision machining on a small scale.

What is peel ply and how does it work?

Peel ply is a special fabric made from materials such as polyamide (PA 6 / nylon) or polyester. It is used in the manufacture of fiber-reinforced plastics (FRP) as a protective and separating layer. It serves to protect the laminate surface from contamination during production and storage and to facilitate processing.

Unlike other reinforcing fabrics, the peel ply does not form a permanent bond with the laminate. It is completely removed before further processing, leaving a clean, rough surface that is suitable for bonding or applying further layers without additional sanding.

When laminating and joining multiple fabric layers, it is crucial that the surfaces are free of grease, clean, and roughened. The conventional method for this is sanding or sandblasting, which is time-consuming and labor-intensive and can cause harmful dust. The use of peel ply GRP is a time-saving alternative, as it protects the laminate surface from contamination and eliminates the need for sanding

Properties and function of peel plies

Protection against dirt and contamination

The fine fabric forms a protective layer on the laminate surface, protecting it from dust, dirt, and other contaminants that can arise during the laminating process or during storage and transport. This layer ensures that the surface remains free of grease or dirt and provides a clean, adhesive-ready base for further processing.

Easy removal and marking

Peel plies are usually equipped with colored indicator threads that make it easy to see whether the fabric has already been removed. This facilitates control in the production process and ensures that the laminate surface is completely exposed. The fabric can be easily removed without leaving any residue, so no reworking is necessary.

Rough, adhesive surface for further processing steps

After removing the fabric, a rough surface remains that is suitable for bonding or applying further fabric layers without additional sanding. This peel ply function is particularly advantageous in projects where several laminate layers need to be bonded or components need to be joined together without the need for time-consuming reworking steps.

Advantages of R&G peel ply

- Savings on sanding costs: The fabric replaces the sanding process, saving time and money and increasing work efficiency.

- Avoidance of harmful dust: Since no sanding is required, there is no harmful dust generated by sandblasting or sanding.

- Optimized lamination process: The fabric enables a clean and rough surface without additional sanding. The remaining surface is adhesive for gluing and laminating work without further processing.

- Easy handling: The peel ply is easy to apply and can be removed effortlessly before further processing.

- Rough surface:

- Indicator threads for control: The colored indicator threads reliably show whether the tear-off fabric has already been removed, which facilitates quality control.

- Versatile fields of application: From the production of non-slip surfaces to use in vacuum processes.

Examples of applications for peel plies

Protection during storage and transport

The fabric protects sensitive laminate surfaces from dirt and contamination during storage and transport. It forms a barrier that keeps the surface intact and clean until further processing, which improves the quality and durability of the components.

Production of non-slip standing surfaces

Peel ply is often used to produce non-slip surfaces on GRP products. In the manufacture of surfboards, sailboats, and refrigerated containers, peel ply can be used to create a rough, non-slip surface that ensures safety and functionality.

Application in vacuum processes

In the vacuum process, the peel ply is applied as the top layer on load-bearing laminates to prevent the suction layer from sticking to the laminate. This facilitates the extraction of excess resin and leaves a clean surface. This application is crucial in the manufacture of heavy-duty composite materials

Protection of the resin surface from oxygen exposure

The peel ply also protects against the effects of atmospheric oxygen, which can impair the curing of the resin surface. By protecting the UP resin from oxygen, the surface remains non-stick and polymerizes completely, ensuring high material quality.

Prevention of composite problems with EP resins

When processing EP resins, bonding problems can arise after only a short time if the surface of the laminate layer is exposed to oxygen. Applying the fabric protects the surface from air and provides an optimal base for further laminating or adhesive layers.

FAQ – Frequently asked questions about tear-off fabric

How does peel ply work?

Peel ply is applied as the final layer to the laminate to protect it from dirt and contamination. It can be easily removed, leaving behind a rough, adhesive surface that can be further processed without sanding.

What is peel ply used for?

Peel ply is used to protect the laminate surface and create a clean, rough base for further processing steps. It is often used in vacuum technology, in the manufacture of non-slip surfaces, and in the GRP sector.

Why is peel ply useful for GRP?

The peel ply protects the surface of glass fibre laminates from dirt and oxygen, which could interfere with polymerization. It also saves time by eliminating the need for sanding and leaving a rough, adhesive-ready surface.

How is peel ply applied?

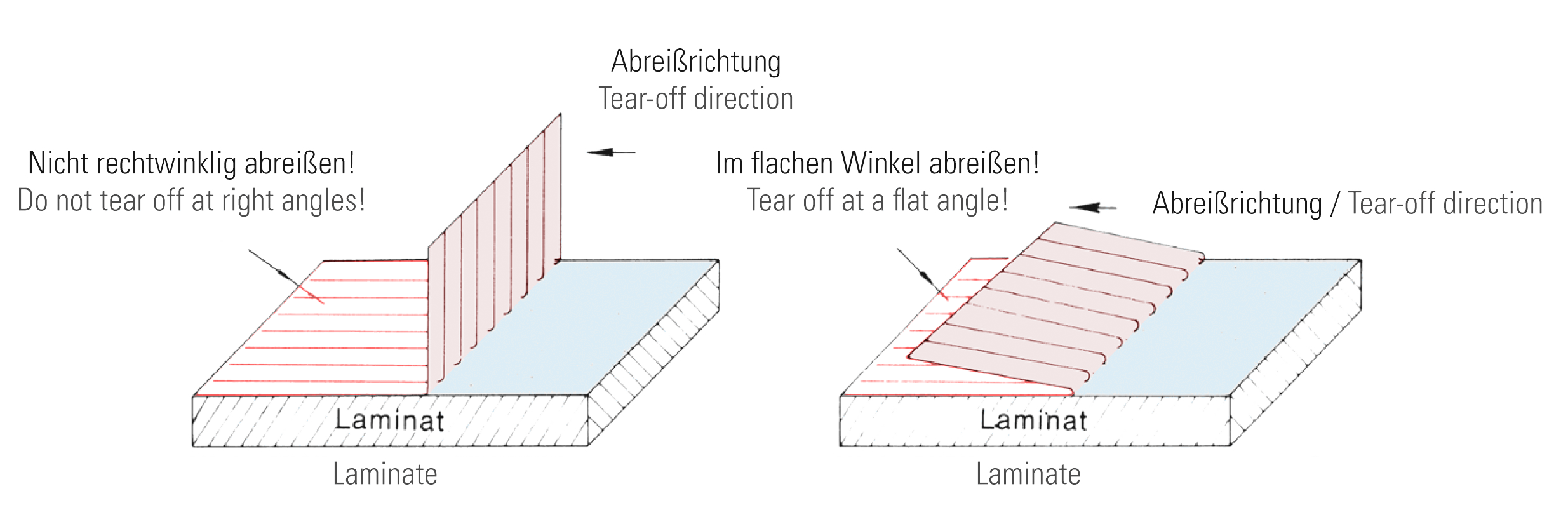

The fabric is applied as the final layer to the still-wet laminate and remains on the surface until further processing. If necessary, it can be removed completely without leaving any residue.

Is peel ply suitable for permanent use?

No, peel ply is not intended for permanent use. It serves as a temporary protective layer during processing and is completely removed before the final use of the component.

What are the advantages and disadvantages of washed and unwashed peel plies?

| Peel ply | washed | unwashed |

| Techncal differences |

Cleaned after the weaving process, which largely removes the sizing. This results in a cleaner separation layer between the fabric and the resin.

|

Contains finishes applied to the yarns at the factory (binding agents that improve weavability and thread stability). Some of this finish remains on the surface of the laminate after the fabric has been removed from it. |

| Effects on the surface and bonding |

Provides a significantly cleaner, adhesive surface immediately after removal. |

Leaves behind microscopic residues of the sizing agent on the component surface. These can significantly impair adhesion during subsequent bonding or coating processes (e.g., painting, filling, gel coating, or secondary laminates). However, this effect can be eliminated by mechanically reworking the surface after removal (e.g., by sanding |

| Processing and handling | Both variants are identical in application: they are applied to the still wet laminate, smoothed out, and removed after hardening. | |

Washed fabric can be slightly stiffer or somewhat more expensive because the washing process requires additional manufacturing steps. In combination with suction fleece or peel ply stack-ups (e.g., in vacuum lamination or infusion processes), washed fabric is particularly advantageous if subsequent processing or bonding is planned. |

||

| Price and cost-effectiveness |

|

More cost-effective, as it is manufactured without an additional washing process. Ideal for applications where no secondary bonding is required. |

| Recommendation from practice | For components that are subsequently glued, painted, or coated, washed peel ply is the better choice—it ensures reproducible good adhesion and saves rework. |

Sufficient and cost-effective for pure lamination processes without further bonding. |

| Conclusion | The choice between washed and unwashed peel ply depends on the planned further processing of the component. | |

If you need a clean, adhesive surface without additional pre-treatment, you should opt for washed peel ply. |

For simple laminating tasks without bonding, the less expensive, unwashed peel ply is perfectly adequate. |

|