Hi-Shrink tape (PTFE-coated on both sides) 25.4 mm, 91.4 m

The shrink tape is a robust, flexible, heat-shrinkable polyester film.

When wrapped around an object and heated, the Hi-Shrink tape starts to shrink and applies pressure to the underlying laminate. Ideally suited for making composite tubes (with the aid of appropriate mandrels).

Product benefits

- A simple way to apply compaction for debulking, consolidating, and forming

- Enables evacuation of excess resin (as well as of volatile compounds)

- Gives your part a high gloss and resin-rich surface finish

- High-performance release coating (non-silicone) on both sides of the tape

- Enables multiple methods for adjusting compressive force on the part

Technical data:

Thickness: 0.05 mm (0.002 inches)

Width: 25.4 mm (1 inch)

Length of roll: 91.4 m (100 yds)

Start of shrinking: 65 °C (150 °F)

Usage temperatures: up to 165 °C (329 °F)

Shrink percentages: 5-20 %

Max. shrink force: 8.59 pounds/inch 1)

Processing:

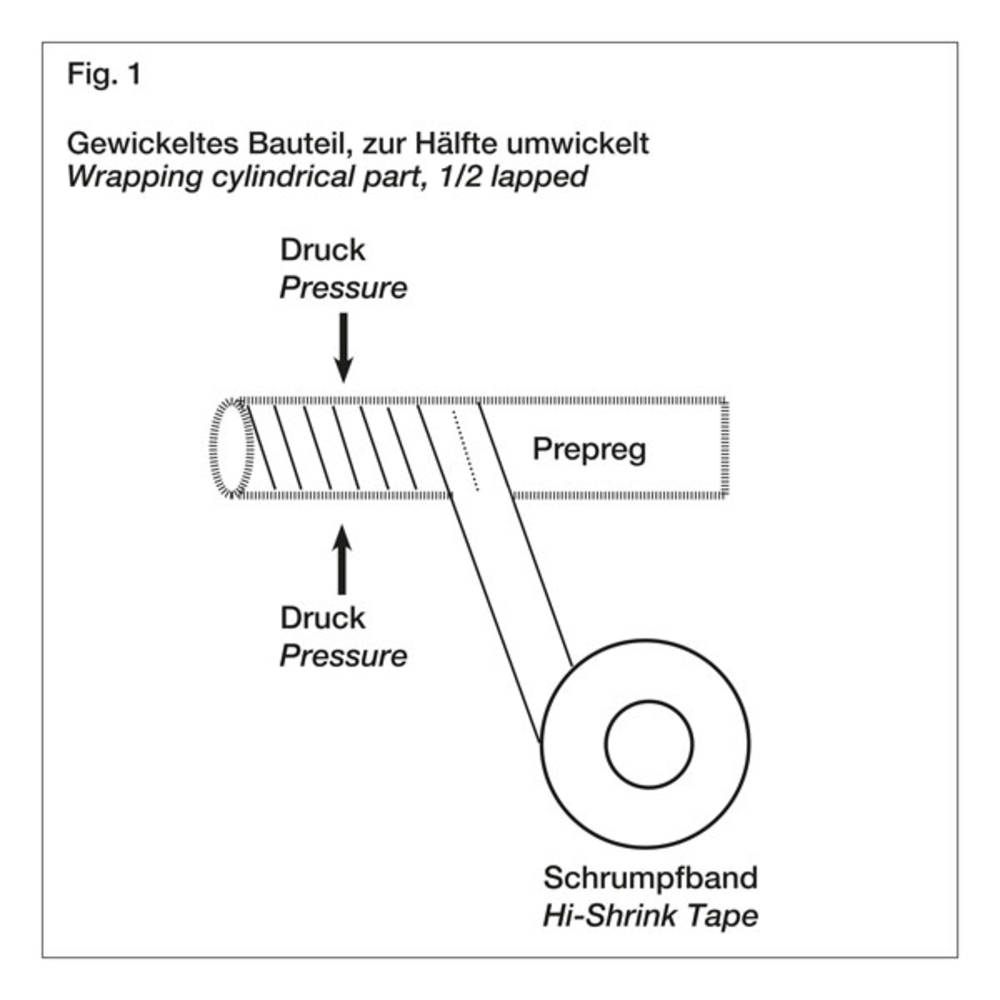

Hi-Shrink Tape may be applied directly to the composite part or over clamping forms. If the part is a tube, rod, or cylinder shape, apply directly over the prepreg and uniform pressure will be applied. (Fig. 1)

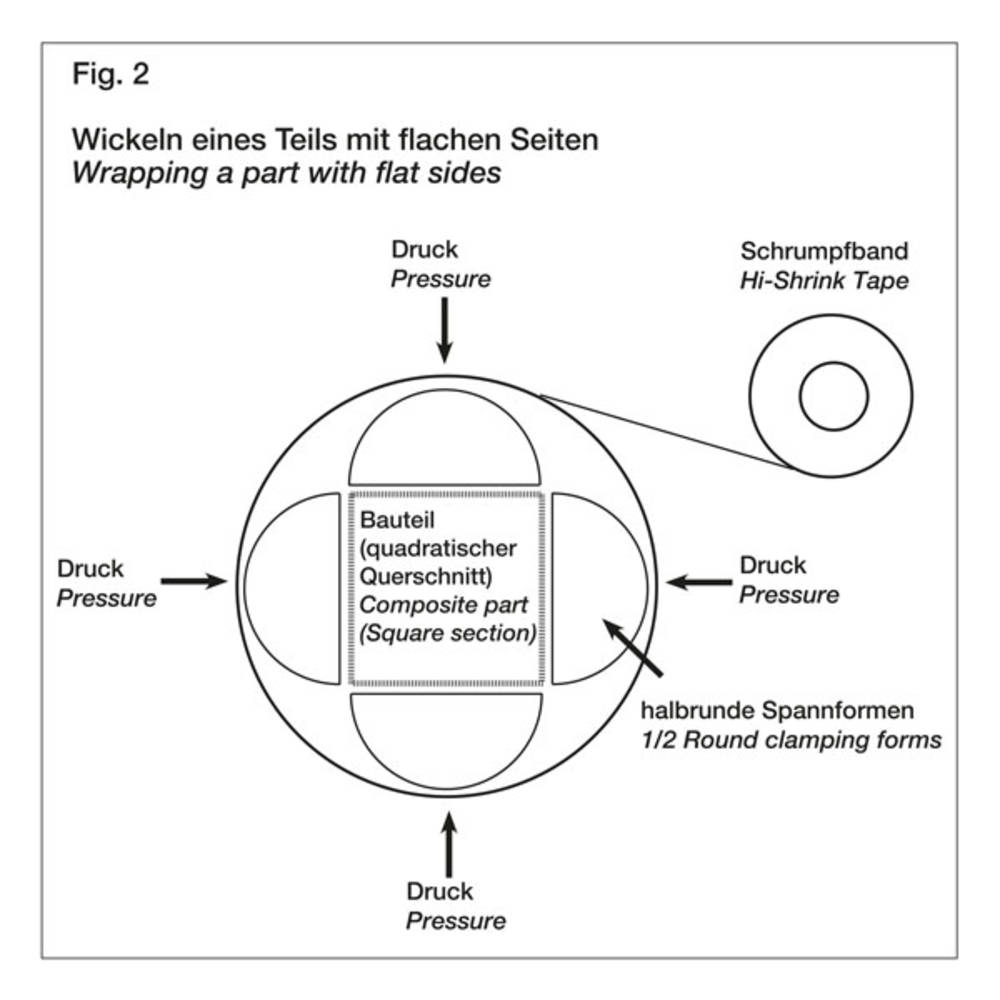

If the part has a rectangular section, taping directly over the prepreg will exert compressive force mainly on the corners. You may wish to apply the tape over simple clamping forms instead so that compressive forces will be applied to the flat sections (Fig.2).

Important:

Both sides of the tape are treated with release agent (PTFE-coated) and is therefore self-releasing.

1) To test the shrinkage strength of the tape, our US manufacturer places a 1.00" wide (= 25.4 mm) sample in a tensile test frame.

The sample is heated in an annealing oven. As the tape shrinks in the linear (machine) direction, it exerts a force of 8.59 lbs (=1.5 N/mm) on the load cell.