Silicone rubber CLEARSOFT ADDV-612 CLEAR (set of two comp.)

Assortment adjustment. This discontinued item is qualitatively perfect goods without defects. Sale while stocks last.

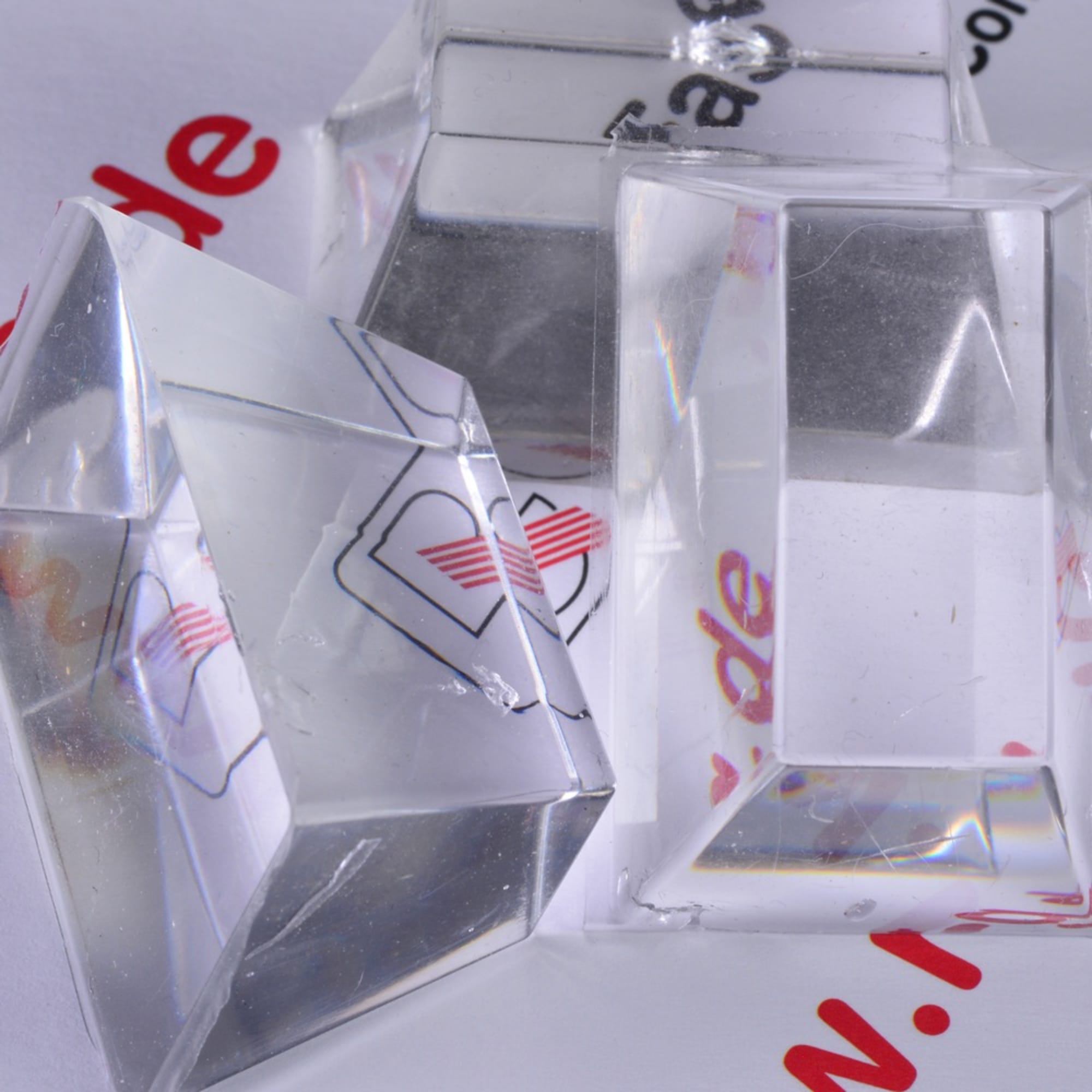

ADDV-612 CLEARSOFT is a pourable, addition-curing 2-component RTV silicone rubber that vulcanizes at room temperature to a very soft silicone gel

- Low viscosity

- Fast heat curing

- Very low hardness (silicone gel)

- Crystal clear

- Flame retardant, UL-listed 94HB

Application:

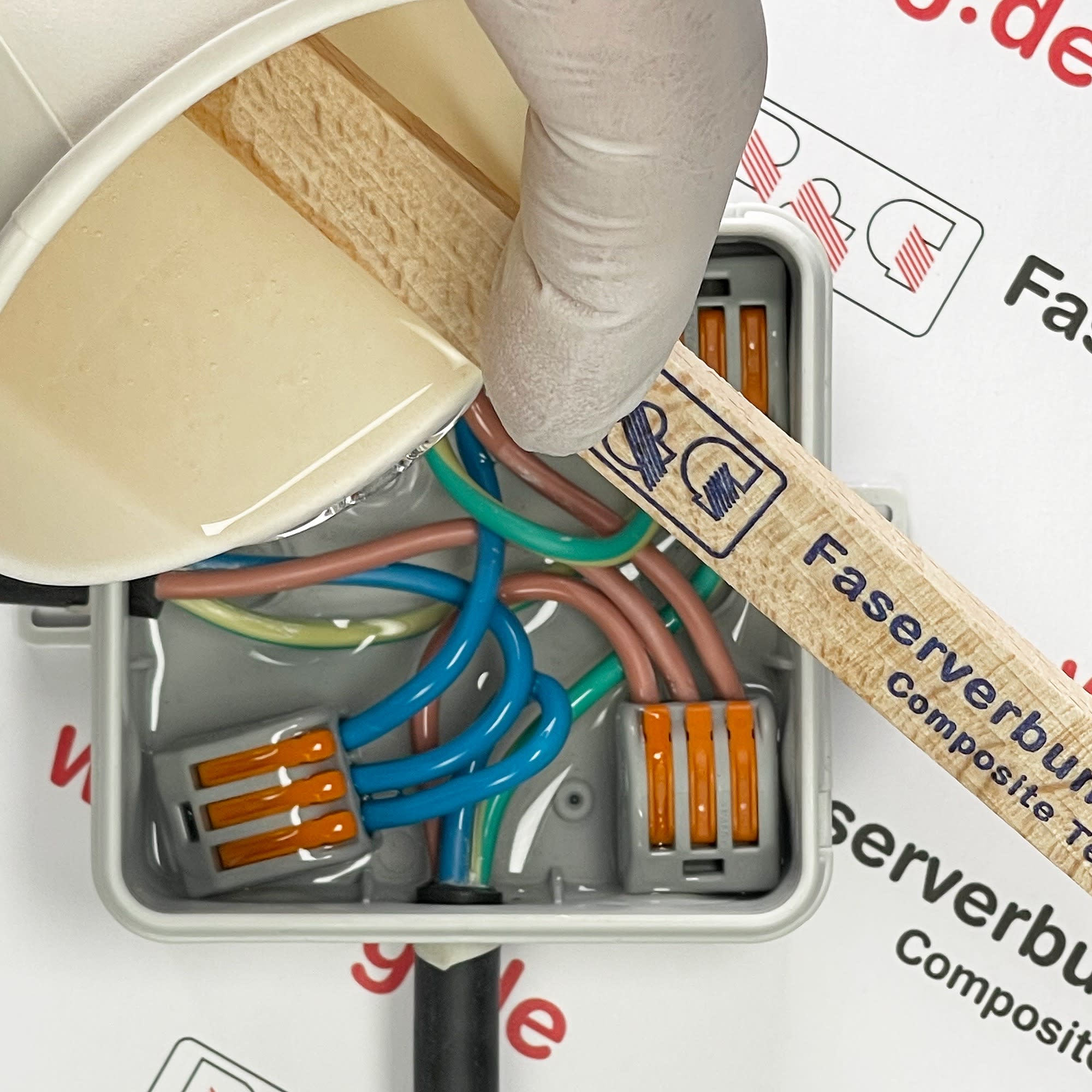

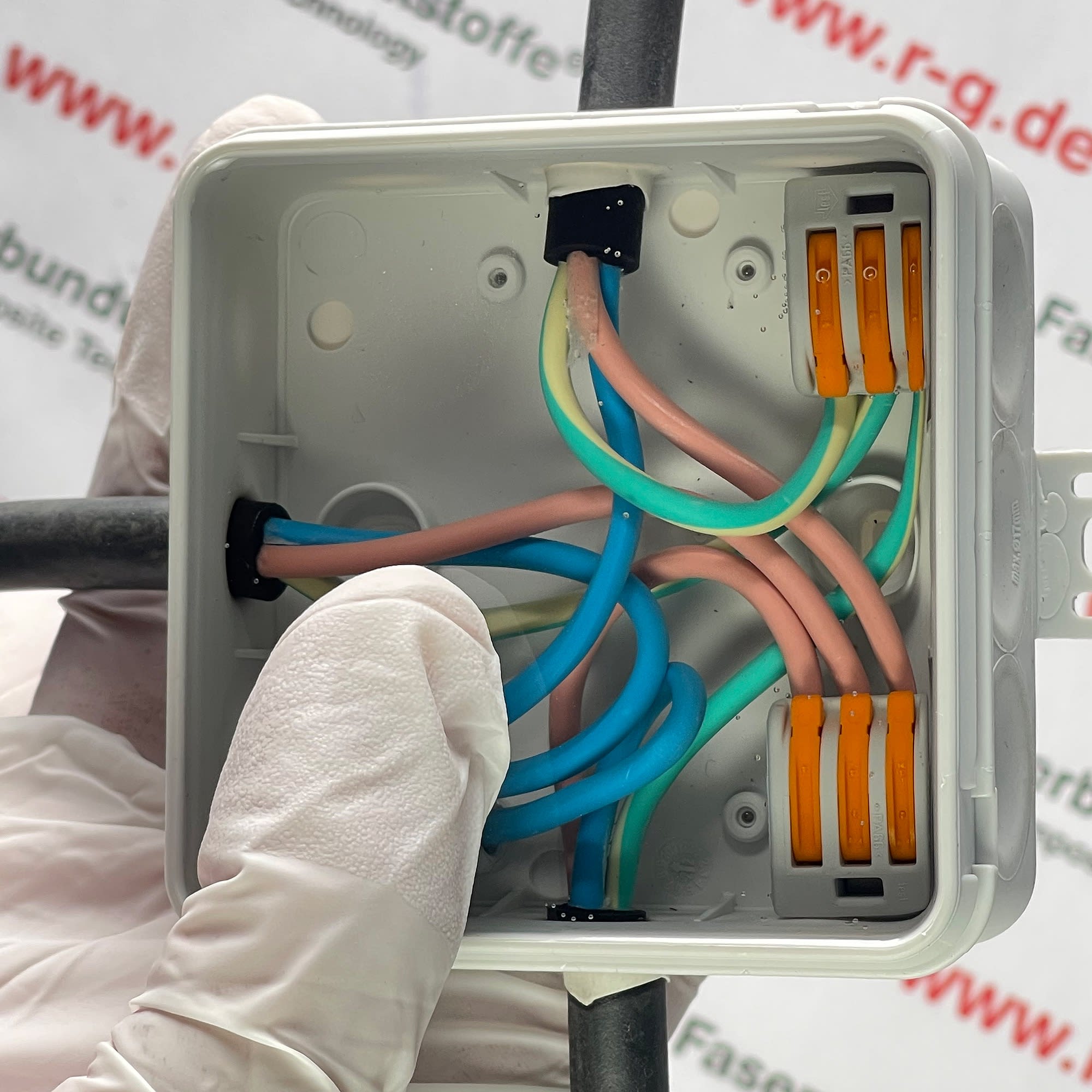

- Casting/encapsulation of electronic components

- The bearing of shock-sensitive components (e.g. in model aircraft construction / in drones etc.)

- Production of damping elements for sealing and production of special seal

Processing:

Mixing ratio: 2 : 1 parts by weight component A : component B

Processing time (at 23 °C): 150 minutes

Demoulding time (at 23 °C): 8 h

Please note:

- Cannot be processed with our Universal Colour Pastes.

- The air stirred in during mixing can be removed by vacuuming in a desiccator. This makes the silicone maximally free of air bubbles.

- With all equipment and tools used, care should be taken that no other materials such as epoxy resins or condensation-curing silicones have been processed with them beforehand. Addition-curing silicones may react to impurities with curing problems.

Technical data:

Component A

Colour: Clear (colourless)

Viscosity (at 23 °C, ISO 3219): 1000 mPa.s

Density (at 23 °C): 0.97 g/cm³

Flashpoint: > 242 °C

Component B

Colour: Clear

Viscosity (at 23 °C, ISO 3219): 1000 mPa.s

Density (at 23 °C): 0.97 g/cm³

Flashpoint: > 200 °C

Mixing viscosity: 1.000 mPas

Hardness Shore A: 10±3

Refractive index nD²⁵ (at 25 °C): 1.404

Additional information:

Delivery:

As both component batches are matches to each other, we only supply complete batches. It is not possible to obtain individual deliveries of silicone and catalyst.

Packs of 0.75 and 1.5 kg are supplied in squeeze bottles.

Customer information:

The release agent Semiperm™ Monofilm in combination with PARTALL® Coverall Film PVA is suitable as a safe release agent for silicone moulds. This combination of release agents provides a barrier layer so that casting with epoxy resins is also possible without any problems. The service life (durability) of the moulds is considerably extended.

The release agent Semiperm™ Monofilm is applied with a brush. After flash-off, PARTALL® Coverall Film PVA is applied, also with a brush or sponge. For more information on the application, see the release agents.

The PARTALL® Coverall Film PVA is transferred to the casting, washed off with water after demoulding and reapplied before each impression.