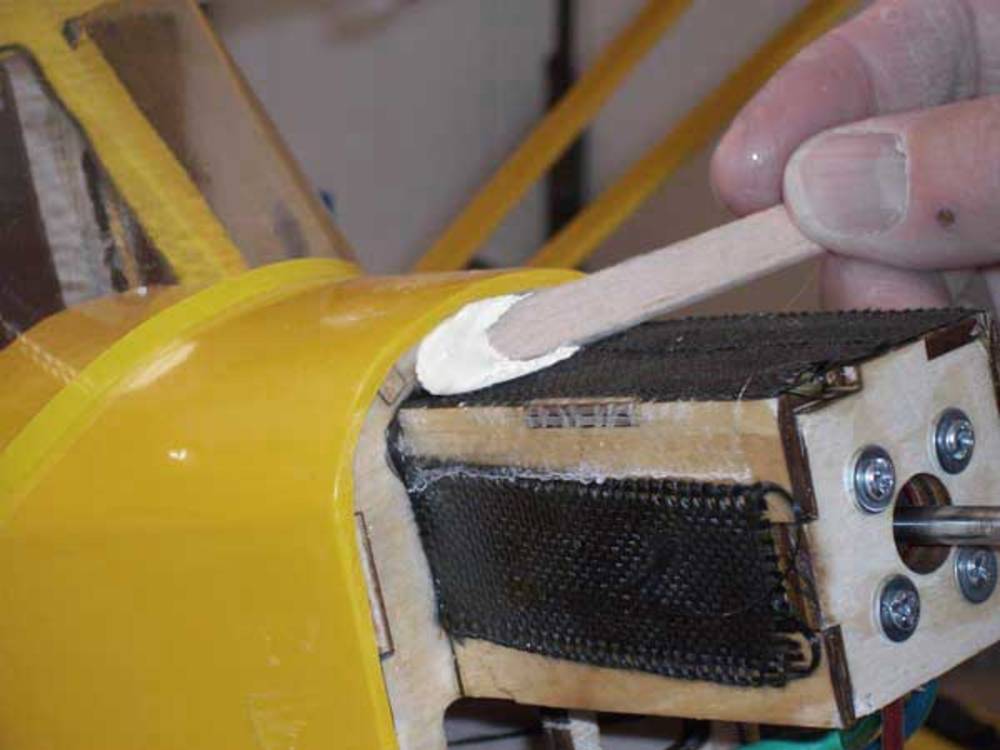

Micro-Ballons™ 0.19 g/cm³, white

Microscopic hollow spheres based on borosilicate glass.

• Yields lightweight and easily sandable filling compounds

• Economical light filler

• For epoxy, polyester, and vinyl ester resins

Micro-Ballons™ are borosilicate glass-based microscopic hollow spheres and are primarily used to reduce the weight of plastics, rubber, cement, etc., but also they have other advantages in a wide range of applications. Some of the advantages such as an increased amount of filler and improved rheology result from the spherical shape of the product.

Micro-Ballons™ make it possible to reduce the weight of plastic components by up to 30 %, increase dimensional stability, abrasion resistance and surface hardness, while reducing thermal expansion.

In addition, the low thermal conductivity results in excellent thermal insulation.

Due to their perfect spherical shape, their use also increases precision in manufacturing as well as the dimensional stability and heat resistance of components.

The common assumption that "weight reduction = additional costs" does not necessarily apply here: with Micro-Ballons™, the weight of components can be reduced without having to increase manufacturing costs.

Properties:

- Low density

- Spherical

- Pourable

- Inert

Advantages:

- Lighter

- The increased amount of filler

- Improved pourability

- Less shrinkage

- Less water absorption

Technical Data:

|

Density (g/cm3)

|

Particle size3

|

Maximum working pressure

|

| Effective1 |

Bulk2 (tamped) |

Mean (microns) |

Range (microns) |

Isostatic (psi) |

| 0.19 |

0.11 |

75 |

5-175 |

500 |

1 Effective Density is the particle density as measured by liquid displacement. True Density is the particle density as measured by gas displacement.

2 Bulk Density is the weight as measured in a container (graduated cylinder, to simulate a bin, silo, or carton) and includes the interstitial air.

3 Data represent percent volume distribution measured using a laser light scatter technique.