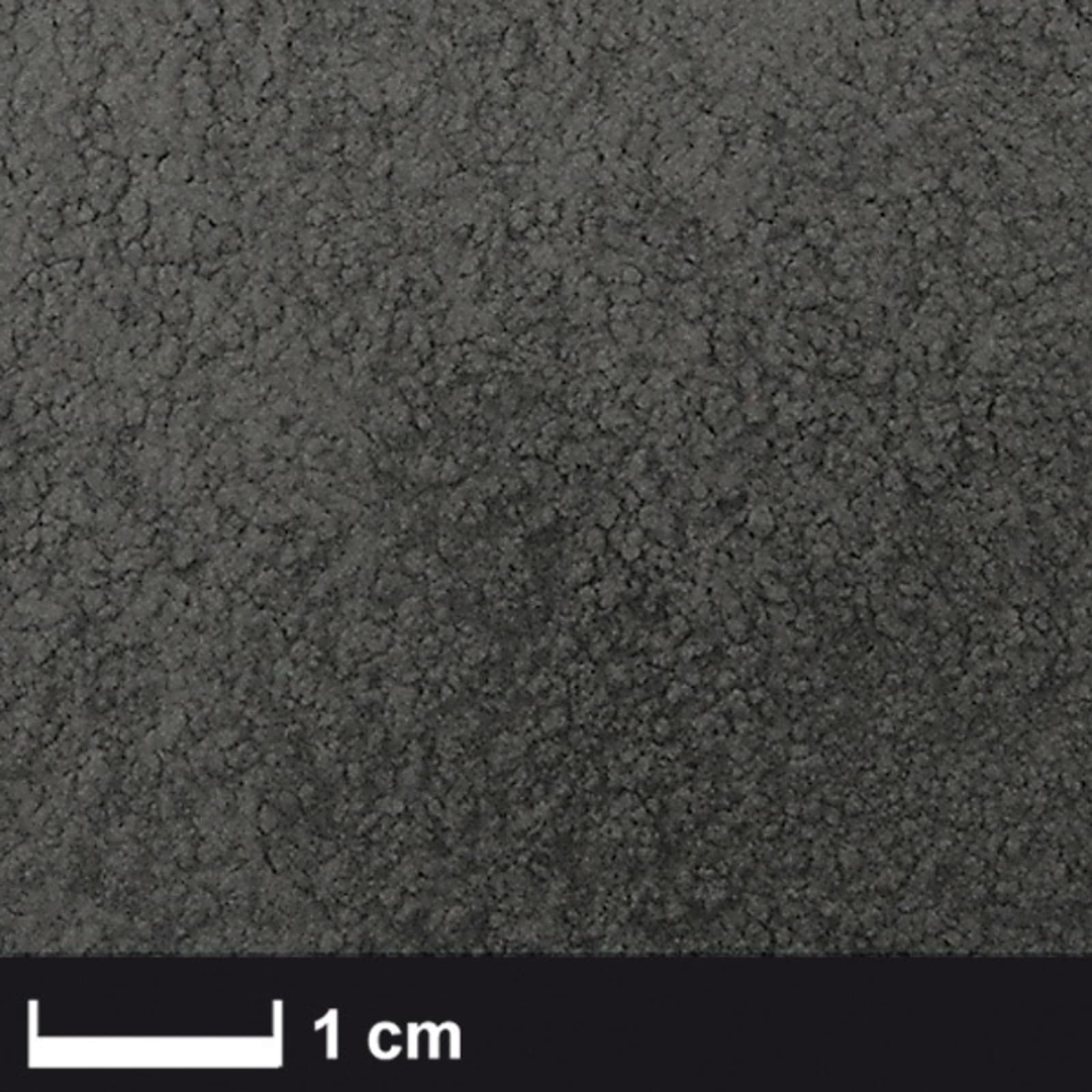

Carbon fibre milled extra fine 0.1 mm

- Yields lightweight, hard filling compounds

- For epoxy, polyester, and vinyl ester resins

Milled carbon is made from recycled fibres. The carbon fibres used therefore are equipped largely with PU-sizing. Most of the sizing evaporates due to heat generated at the milling process though. When dry the milled fibres form fibre balls, which dissolve and spread out evenly in resin.

Technical Data*:

Carbon fibres content: 100 % (99 %)

including ex-PAN fibres: > 90 %

Carbon content: 94 % (92 %)

Density (g/m³): 1.7 < d < 2.0

Monofilament diameter: 7 µm ± 2

Volume resistivity (average volume resistivity of n (n > 1000) monofilaments): 15 µΩm (max. 20)

Tensile strength: 3500 MPa (3000)

Elongation at break: 1.5 % (1,2)

Tensile modulus: 230 GPa

Median length: 100 µm ± 20

Application:

Manufacture of electrically conductive coatings and adhesives, reinforcement of moulding and fillings.

*Average values obtained from technical data sheets of producers of ex-PAN ‘‘high strength’’ fibres that we use in our mixture for more than 90 %. The ≤ 10 % remaining are ‘‘high modulus’’ fibres from the same producers, i.e. TORAYCA®, TOHO-TENAX, CYTEC... All these values are given as a rough guide.