300 g/m² / 8.8 oz/yd²

Medium-heavy, highly drape-able, and soft-needled non-woven.

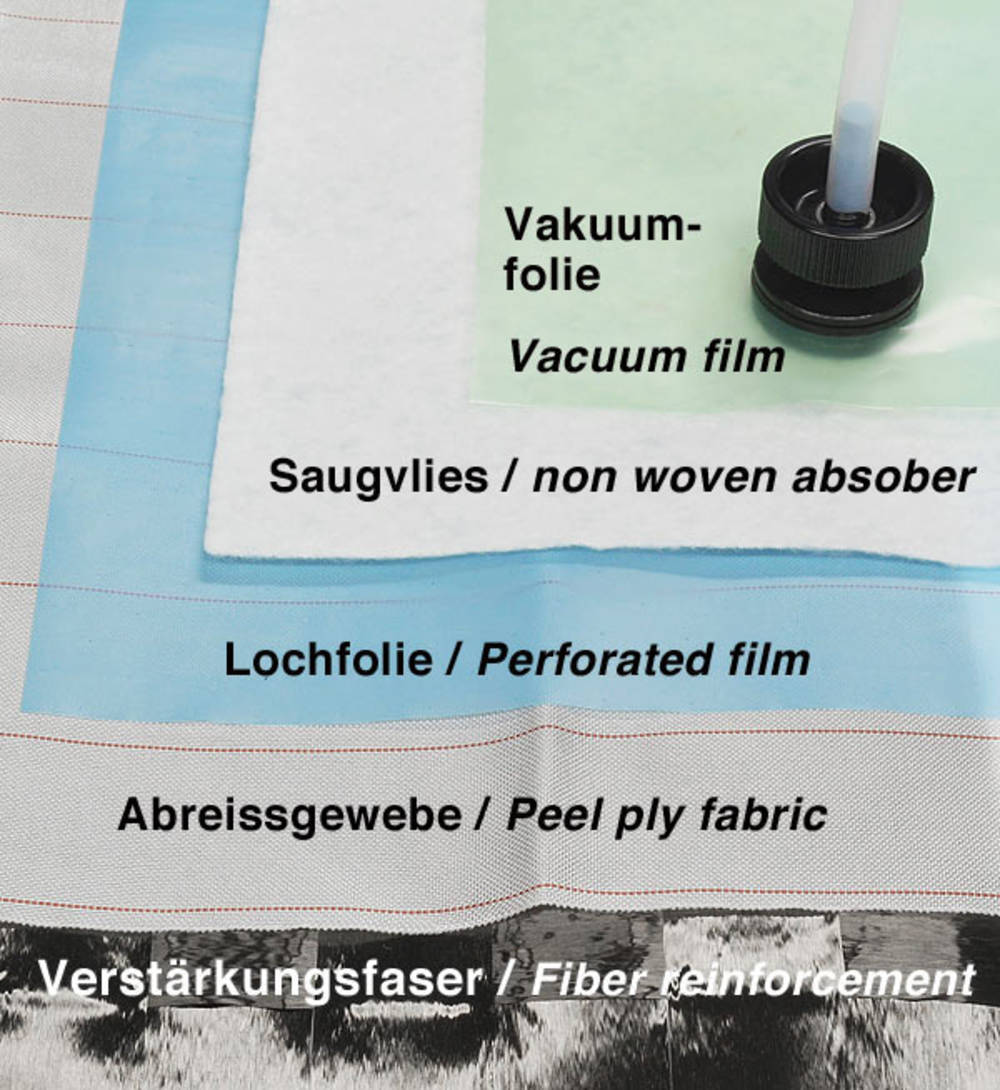

Use as absorbent non-woven

Absorber for taking up excess resin forced through the perforated film when the laminate is evacuated. This non-woven absorber is used in one or more layers.

The absorbent fleece is mainly used for vacuum pressing and is not suitable for vacuum infusion as it soaks up resin and slows down the flow front. Flow aids for infusion have a lower flow resistance, which accelerates the flow front as they create a gap between the vacuum film and the textile. However, in some cases, such as the coating of rigid PVC foam sheets for spar push bars in wing construction, it is important that not too much resin is absorbed during vacuum pressing, as this could impair the bonding.

Use as mould non-woven

This stretchable non-woven is ideal for creating freehand moulds. In-car manufacture, it is used for making door panels for built-in loudspeakers, etc.

It can be easily impregnated with epoxy and polyester resins and yields coat thicknesses from about three millimetres. These wall thicknesses often render further reinforcement with glass fibre plies unnecessary and help to save a great deal of grinding work. Resin uptake per layer approx. 2.2 kg/m².

Technical data:

Max. temperature: 205 °C

Thickness (uncompressed): 2.5 mm (0.1 ")

Weight: 300 g/m²

Pressure: max. 7 bar (autoclave)

Width: 152 cm

(= 1.52 m²)

Item no. 3901821 Only 5 left in stock, more on the way (delivery time 1-2 days)

(= 7.60 m²)

Item no. 3901824 Only 2 left in stock, more on the way (delivery time 1-2 days)

(= 15.20 m²)

Item no. 3901825 Only 2 left in stock, more on the way (delivery time 1-2 days)

(= 30.40 m²)

Item no. 3901826 Only 2 left in stock, more on the way (delivery time 1-2 days)

(= 76 m²)

Item no. 3901827 Only 3 left in stock, more on the way (delivery time 1-2 days)

Scaled Price

all Prices price incl. VAT, possibly plus shipping