- NEW

- SALE

- SPECIAL OFFERS

- Resins + Hardeners

- Epoxy resins

- Polyester resins

- Processing method

- Laminating

- Casting

- Vacuum infusion/RTM

- Special products

- Epoxy

- Gelcoats

- Mould resins

- Colour pastes + additives

- Glues / Fillers

- PU-foams

- Silicone moulding compounds

- Release agents /Solvents

- Fibre reinforcements

- Carbon semi-finished products

- GFRP semi-finished products

- Carbon-Prepreg

- Fillers

- Sandwich material (Honeycombs, Foam)

- Safety equipment

- Tools / aids

- Vacuum technology

- Media

- Mould making

- River Tables

- CFRP-Machining

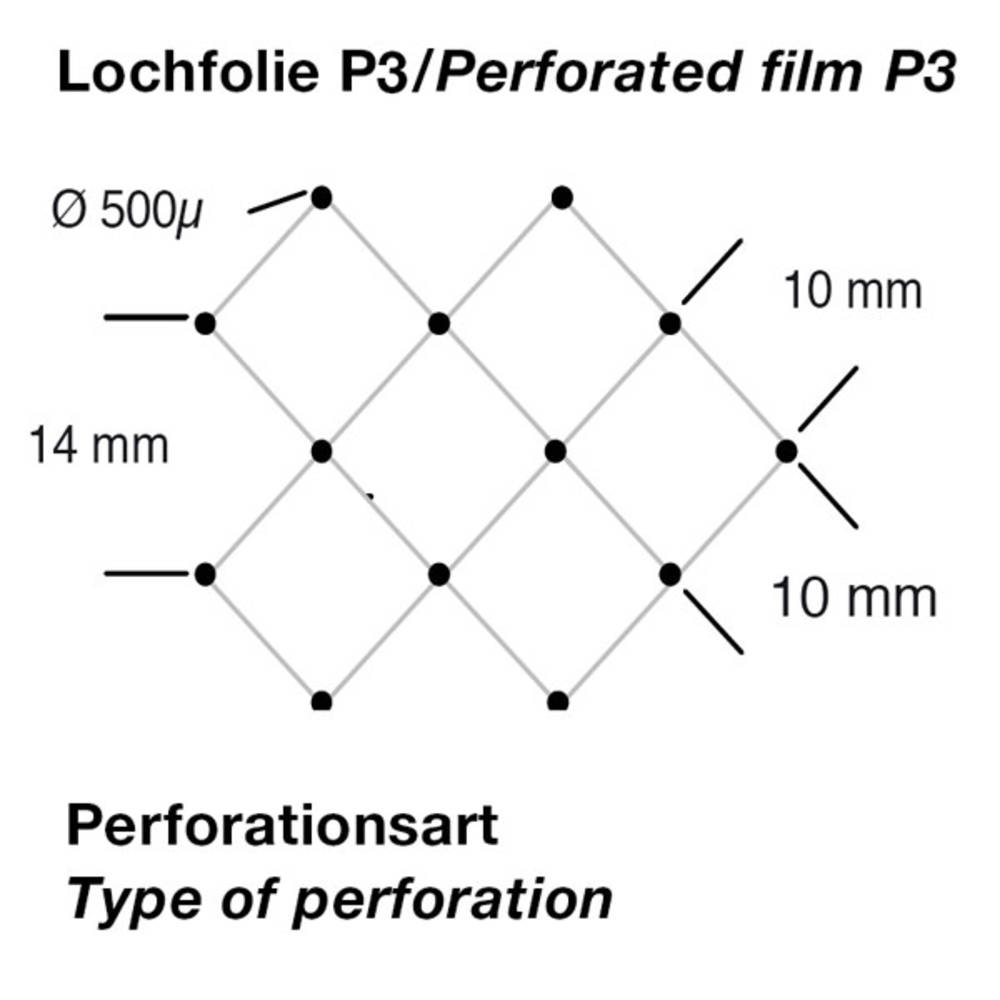

Bagging film RED perforated (P3) 25 my, 122 cm

Perforated FEP* fluoropolymer bagging film, providing a release from all commonly used resin systems, throughout a wide temperature band (from ambient to 260 °C).

This FEP film provides a glossy surface. It can also be used for the high-temperature infusion process.

Fluoroplastics such as FEP are characterized by their:

- Flexibility

- Good weldability

- High-temperature resistance

- Excellent chemical resistance

- Applicability in the low-temperature range

- Usability in high-purity applications

- Long life

- Electrical resistance

- Simple thermoplastic processing

Temperature service range: -200 °C : +260 °C (min : max)

Thickness: 0.025 mm (25 µm)

Width: 122 cm

Max. elongation: Approx. 300 %

Weight: 54 g/m²

Tensile strength: 20 MPa

Colour: Red

*Fluorinated ethylene propylene

Caution: Only conditionally suitable for processing in autoclaves.

Technician tip

(Thomas Nothdurft, application engineer at R&G)

The material can be used up to a maximum temperature of 260 °C. However, autoclave-assisted processing can cause problems, as the resin, which has a very low viscosity at around 120 °C, migrates through the holes in the fleece and leaves pinholes. It is therefore important to note that the material is only suitable for autoclave processing to a limited extent.

To prevent the resin from migrating into the fleece, we recommend the following procedure:

- Insert the prepreg layers.

- Optionally, a peel ply can be applied.

- This is followed by a perforated film and then the vacuum suction fleece.

- Cover everything with a vacuum film and create a vacuum. Press everything down firmly and use a hot air dryer to make the prepregs drapable.

- After the first deaeration process, remove the perforated film and replace it with a non-perforated film.

- Create a vacuum again and optionally place the whole thing in the autoclave to start the temperature cycle.

The non-perforated film means that no resin can migrate, resulting in good, pinhole-free surfaces. For optimum results, we recommend a curing temperature of of at least 120 °C or higher. At this temperature, the viscosity of the resin becomes extremely low, resulting in better surfaces, especially if the process is carried out in an autoclave at higher pressure.

Autoclaves are unfortunately expensive, so not every user has access to this technology. The steps mentioned above also lead to good results in a vacuum with ambient pressure, an autoclave is not absolutely necessary.

Bagging film RED, P3 (- PERFORATED -) 122 cm, roll/ 5 m

Item no. 390500-122-P3-4 Only 1 left in stock, more on the way (delivery time 1-2 days)

Bagging film RED, P3 (- PERFORATED -) 122 cm, roll/ 10 m

Item no. 390500-122-P3-5 Only 11 left in stock, more on the way (delivery time 1-2 days)

Bagging film RED, P3 (- PERFORATED -) 122 cm, roll/ 20 m

Item no. 390500-122-P3-6 Only 1 left in stock, more on the way (delivery time 1-2 days)

Scaled Price

- From Qty 2: 5,00%

- From Qty 5: 10,00%

Bagging film RED, P3 (- PERFORATED -) 122 cm, roll/ 153 m

Item no. 390500-122-P3-9 Delivery time on request

Scaled Price

- From Qty 2: 5,00%

all Prices price incl. VAT, possibly plus shipping