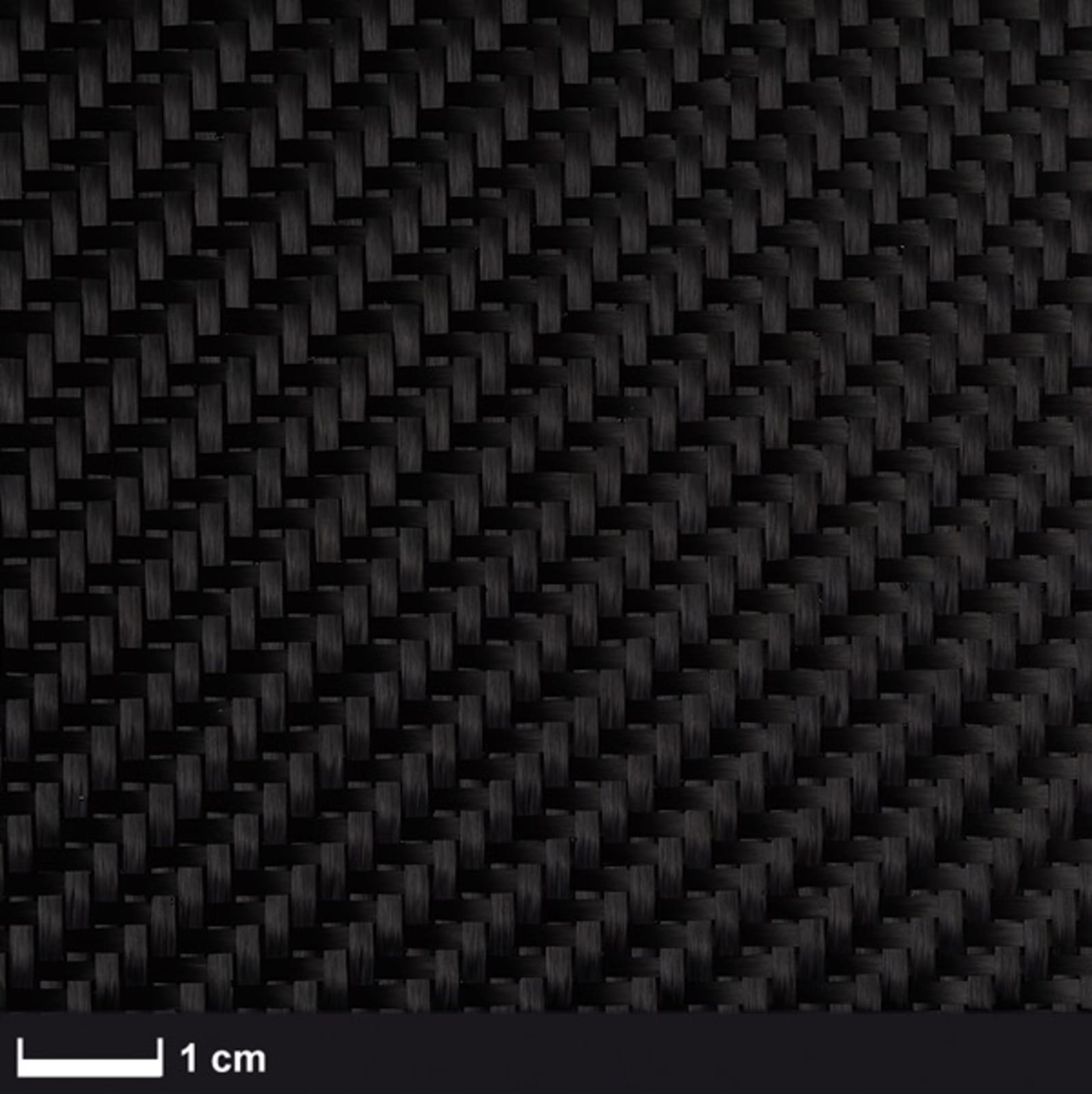

Carbon fabric 200 g/m² (style 452-5-aero, twill weave, non-shift) 100 cm

USA: width 39.37", weight 5.9 oz/yd²

Fibre: Tenax® HTA 40 E13 / 200 tex (3k), alternatively Pyrofil™ TR30S (carbon fibre according to material performance sheet WLB 8.3611 (high-strength yarns for aerospace applications)

Style 452-5-aero, non-shift

Material as per aviation standards

Twill weave

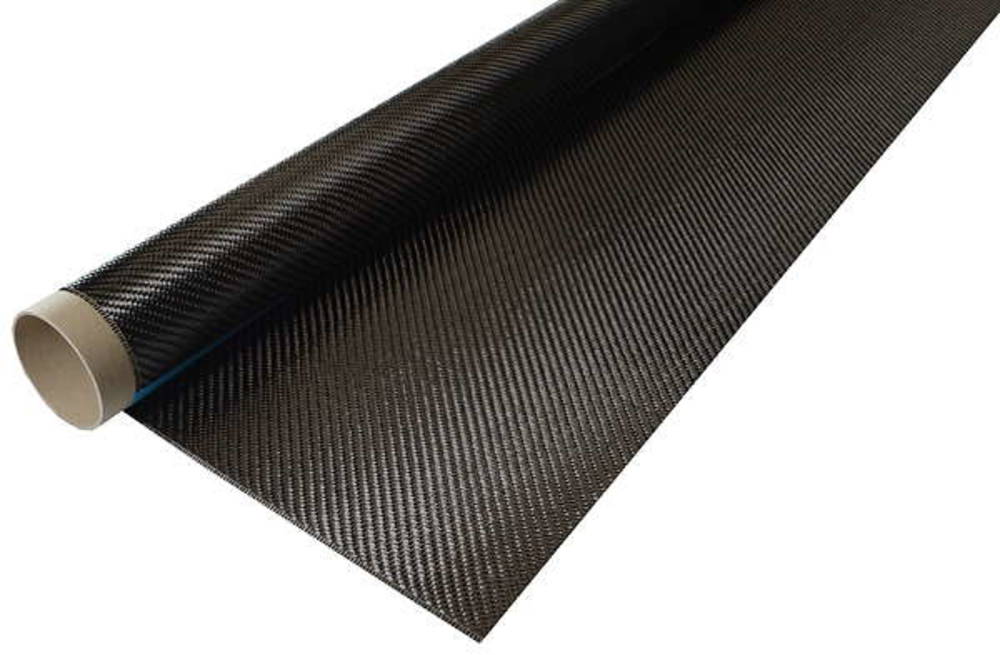

Width: 100 cm

Setting (Thr./cm): 5 x 5

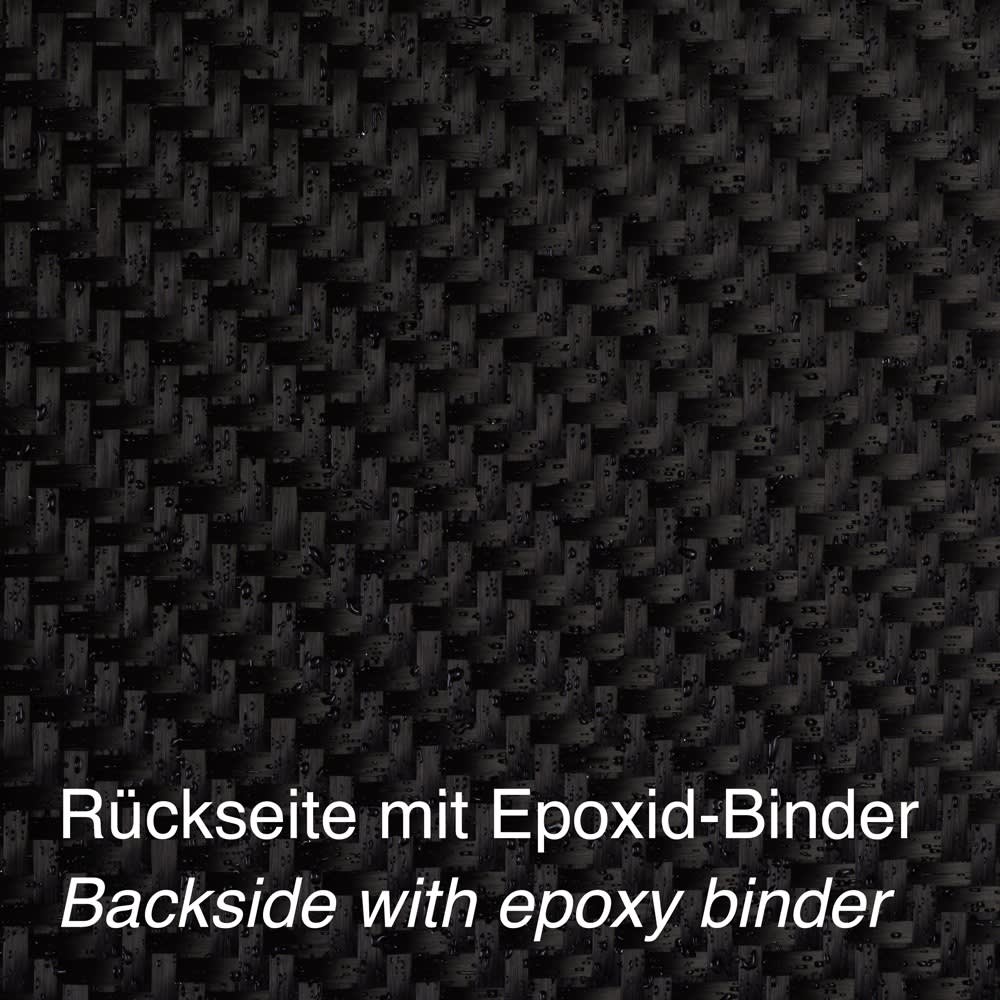

Basic weight 200 g/m² + 10-15 g/m² EP binder

Application:

Supporting parts in aircraft construction, motorsports, marine construction and modelling, carbon design

The fabric is coated on one side with an EP-Binder, backside is smooth.

The EP binder prevents slippage, so cut pieces do not loose threads. Heat (pressure mould) can be used to preform the fabric before impregnation with resin. Specifically for carbon designs in automotive engineering. Even an iron on the surface (eg during coating of surfaces) is possible. The fabric will be formed only and has additionally to be impregnated with resin.

If the fabric is processed during normal hand laminating without melting the binder, please make sure that the smooth side is placed on the later visible side of the mould. Otherwise too many small air bubbles will form because the fabric does not lie flat due to the "droplets" of the EP binder.

Calculated data for hand laminates with 35 volume per cent fibres:

Resin consumption: 241 g/m², laminate thickness: 0.32 mm, laminate weight: 441 g/m²